A Guide to Unscrewing Mold Technology for Molding Threaded Plastic Parts

Unscrewing mold technology provides an innovative method to mold internal and external threads in plastic parts using collapsible, unscrewing cores and cavities. This enables accurate molding of threads, helical gears and other challenging geometries impossible with standard molds.

This guide covers the fundamentals of unscrewing mold construction, operation, advantages, limitations, costs, and typical applications that can benefit from this technology.

What is Unscrewing Mold Technology?

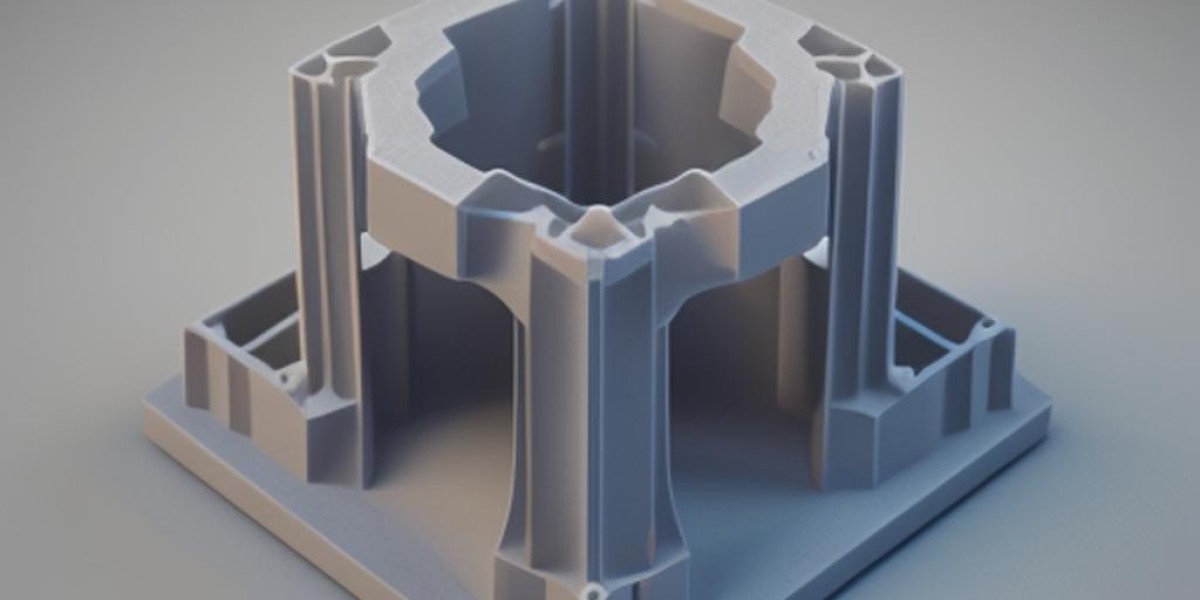

Unscrewing molds utilize special tooling that collapses and unscrews sideways to mold complex internal spiraling undercuts. The cores are split into segments that contract or expand to release the molded threads or gears after solidification.

Key components of unscrewing molds:

- Split threaded core halves that mesh together in the mold.

- An unscrewing mechanism to rotate the core halves apart.

- Contractible cavity components to enclose the core.

- Precise synchronization to control core collapse and expansion.

Unscrewing enables molding of geometries impossible with normal straight-pull molds.

Why Use Unscrewing Molds?

Unscrewing molds provide several unique advantages:

- Mold internal and external screw threads, helixes, gears.

- No side actions needed - compact mold.

- Demold parts with complex undercuts easily.

- Excellent dimensional accuracy and surface finish.

- Automated operation for high productivity.

- Avoid sink marks in deep recesses.

- Reduce secondary tapping/threading operations.

Due to these benefits, unscrewing is ideal for molding precision threaded plastic components.

Typical Applications of Unscrewing Molds

Some common applications include:

- Closures - caps, lids, bottles with threads

- Medical components - syringe barrels, fittings

- Automotive - oil filters, pump housings, fasteners

- Consumer goods - jar lids, spray triggers

- Industrial - valves, connectors, nozzles

Any part with challenging internal spiraling geometries is a good candidate for unscrewing molding.

How Does Unscrewing Mold Technology Work?

The key stages in unscrewing mold operation are:

Clamping

The mold closes and the segments mesh together, creating the core and cavity shape.

Injection

Plastic fills the cavity through a side gate, flowing smoothly over the threaded surfaces.

Cooling

Plastic solidifies into the molded shape, encapsulating the meshed core threads.

Unscrewing

On mold opening, the core halves unsync and unscrew sideways to collapse the core and release undercuts.

Ejection

Finally, the finished part is ejected out of the cavity. The mold resets for the next cycle.

Repeating this sequence continuously produces threaded plastic parts.

Design Guidelines for Unscrewing Molds

Some design considerations for unscrewing molds:

- Core strength should allow meshing without collapsing during injection.

- Moving components must have adequate clearance for rotation.

- Cooling channels provide faster, even solidification of threads.

- Sufficient draft enables easy demolding of threaded surfaces.

- Part geometry is modular for splitting core sections symmetrically.

- Gates located off center for easier demolding.

- Robust assemblies prevent misalignment during cycling.

When designed properly using these principles, unscrewing molds offer very reliable performance.

Unscrewing Mold Components

Unscrewing molds utilize special components:

- Interlocking core pin segments that mesh together into threads

- Dividing housing splits threaded core sections

- Indexing plates control rotation sequence of core parts

- Servo motors or cams to drive timed unscrewing

- Precise guides/tracks for smooth core motion

- Expandable cavity rings enclose threaded cores

These custom mold components enable the unscrewing action and controllable operation.

Limitations of Unscrewing Molds

Some limitations include:

- Complex and expensive molds. Require expert design and machining.

- Only feasible for shorter, uniform threads. Long spirals are challenging.

- Strict process control needed for reliable cycling.

- Higher parting line on outer threads may require trimming.

- Not recommended for abrasive filled plastics.

- Tight tolerances required between locking segments.

Unscrewing is technically demanding but produces excellent molded threads when executed correctly.

Cost Considerations

Unscrewing molds have a higher cost due to:

- Intricate components and machining

- Tighter tolerances required

- Advanced mold design

- Specialized mold maker experience

- Automation mechanisms

However, this is offset by lower part costs, higher cavitation, and avoiding secondary threading operations.

Conclusion

Unscrewing mold technology enables high precision molding of complex internal spiraling undercuts like threads and helical gears which are otherwise impossible to mold. Though technically demanding, unscrewing molds provide a cost-effective solution when designed and manufactured correctly.

China's extensive plastics manufacturing ecosystem provides access to advanced mold components, machining capabilities, and qualified resources to implement unscrewing molds cost-effectively. Partnering with integrated Chinese mold makers that offer comprehensive design, tooling, quality and secondary services results in high-performance unscrewing molds tailored to the specific application needs.