Title: Mastering Undercut Design for Injection Molded Plastic Parts

Slug: injection-molded-plastic-part-undercut-design

Meta description: Undercuts present challenges in injection molding plastic parts. Learn about undercut types, design guidelines, mold solutions like side actions to enable undercut molding.

Mastering Undercut Design for Injection Molded Plastic Parts

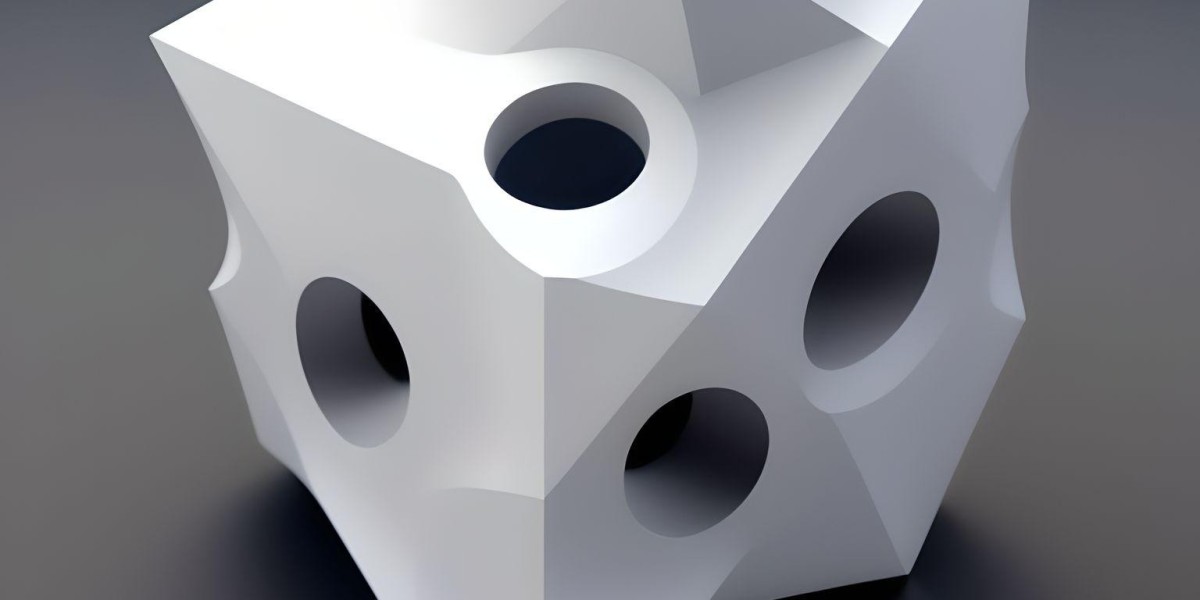

Undercuts are common features in injection molded plastic parts that present unique challenges during molding. Undercuts are re-entrant geometries that cannot be molded using simple straight-pull molds. Smart undercut design coupled with the right mold solutions enables manufacturing parts with otherwise impossible shapes.

This guide covers undercut types, design considerations, analysis methods, and mold technologies like side cams, unscrewing molds, collapsible cores that make undercut injection molding feasible.

What are Undercuts in Injection Molded Parts?

Undercuts are inward protruding geometries in plastic parts that obstruct clean straight-line demolding from a simple two-plate mold. They create an ‘undercut’ which locks the part in the mold upon solidification.

Common examples include internal hooks, tabs, ribs, threads, slots, snap fits, holes, and other recessed shapes that ‘undercut’ the surface. Undercuts require the mold to move sideways, rotate or collapse to eject the part after molding.

With careful analysis and the right mold design, even complex parts with undercuts can be injection molded successfully.

Importance of Undercut Analysis

Analyzing parts for undercuts is critical for several reasons:

- Determines if a part is moldable or not

- Identifies required sliding/rotating mold actions

- Avoids expensive mold reworks due to unaccounted undercuts

- Provides data for building feasibility into the part design

- Allows quoting accurate mold costs

- Ensures moldability is considered during part design stage

Early undercut analysis provides crucial insights that inform part design, mold design and manufacturability.

Types of Undercuts

Undercuts in molded parts can be classified into three main types:

External Undercuts

These are features like hooks, ribs, projections, lips on the visible exterior surface of parts that obstruct demolding.

Internal Undercuts

Internal undercuts include threads, holes, slots, gears on inner walls and bores that require mold actions to clear.

Re-entrant Angles

Any inward protruding shape at an angle to the demolding direction that blocks straight-line ejection is a re-entrant undercut. Common on inclined surfaces.

Identifying the specific undercut type and geometry helps select the most suitable mold technology to enable molding.

Undercut Design Guidelines

To maximize moldability, parts should be designed with these undercut guidelines:

- Avoid undercuts wherever possible. Design full radii, no recesses.

- Limit undercut depth to allow use of shallow side-actions.

- Ensure uniform wall thickness and avoid ribs in undercut areas.

- Design self-releasing draft angles adjacent to undercuts.

- Keep undercut angles >7° to facilitate minor mold opening.

- Position similar undercuts together to minimize mold actions.

- Make undercuts modular/symmetrical for easier collapsing.

- Allow adequate access around undercuts for cam pins, slides.

Following these early in the design process greatly improves undercut moldability.

Undercut Analysis Methods

There are two main methods used to identify and analyze part undercuts:

Visual Analysis

2D blueprint drawings and 3D CAD models are visually inspected to locate undercuts. The type, position, depth, and access around undercuts is noted. Used for simple parts.

Moldability Analysis

Dedicated moldability analysis software checks parts for undercuts. The exact undercut volume, draft, radius, position are quantified. Automates analysis for complex parts.

These methods provide key data to design the mold, plan any side actions, and ensure complete moldability.

Mold Technologies for Undercut Parts

Undercuts are molded by designing specific mechanisms in the mold:

Side Cores

A plate slides sideways to create the undercut, then retracts to demold the part. Simple and cost-effective.

Side Actions

Multi-plate assemblies slip, rotate or extend to form undercuts and release parts. For complex geometries.

Unscrewing

Core halves collapse together and unscrew sideways to create spiraled undercuts. Used for threads.

Collapsible Cores

Segments collapse or contract into each other after molding the undercuts. Removes deep undercuts easily.

With clever mold design, even seemingly impossible undercuts can be molded. The mold cost also increases significantly.

Automating Undercut Side Actions

Complex molds with many side actions are automated for simplified operation using:

- Hydraulic cylinders that power slides in a controlled sequence.

- Electric servo motors programmed to activate multiple slides/lifters.

- Rotary tables that precisely angle/rotate cores to release undercuts.

- Longer hydraulic or pneumatic tie-bars that allow the mold to open wider.

Automation makes mold operation very reliable even for the most complex side action molds.

Conclusion

Undercuts present unique challenges for injection molding but can be designed and molded with the right analysis approach and mold solutions. Combining smart part design optimized for manufacture along with innovative mold technologies makes molding even geometrically complex undercut parts possible.

China's extensive plastics manufacturing ecosystem provides access to advanced mold components, machining capabilities, and qualified resources to implement complex side action molds cost-effectively. Partnering with integrated Chinese mold makers that offer comprehensive design, tooling, quality and secondary services results in high-performance molds tailored to the specific undercut application needs.