Are you tired of spending endless hours manually applying edgebanding to your woodworking projects? Do you find yourself struggling to achieve seamless results while wasting precious time and resources?

In this article, we will cover a series of tips and tricks that will revolutionize your edgebanding process using the powerful and efficient Homag Edgebander. Let's dive in.

Optimal Machine Setup for Smooth Operations

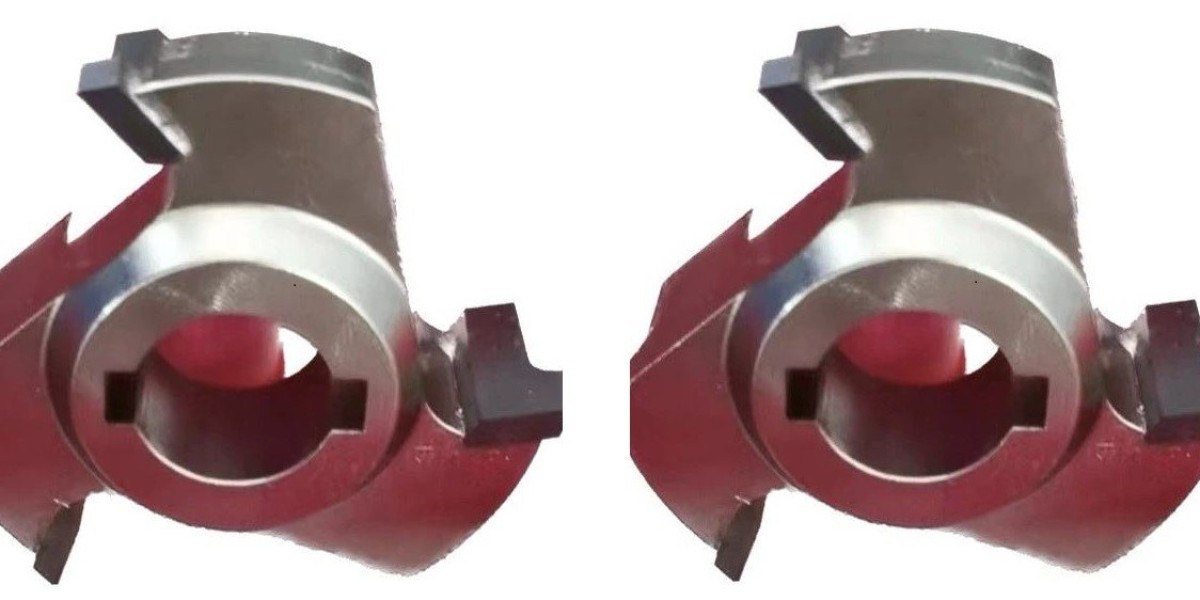

Setting up your Homag Edgebander correctly is the first step towards maximizing efficiency. Ensure that the machine is properly calibrated, the cutters are sharpened, and the feeding system is well-aligned. Be sure to replace your tooling before it dulls to always ensure the cleanest edge quality. By paying attention to these crucial details, you can minimize errors and reduce the need for rework.

For example: Let's say you're working on a large furniture project that requires consistent edgebanding on multiple pieces. By meticulously aligning the Homag Edgebander, you can ensure precise and uniform edgebanding across all the components, saving valuable time in the process.

Choosing the Right Edgebanding Materials

Selecting the appropriate edgebanding materials is essential for achieving high-quality results efficiently.

Thickness is an important factor to consider when selecting edgebanding materials.

Suppose you're working on a project that requires edgebanding on curved or intricate profiles, such as ornate furniture pieces. In such cases, opting for thin edgebanding materials allows for easy application and adherence to the curved surfaces, ensuring a seamless finish.

The Homag Edgebander's precision feeding system and adjustable pressure rollers can accommodate various thicknesses, providing consistent results.

Texture is another consideration when choosing edgebanding materials.

Imagine you're crafting a rustic-style wooden coffee table with a textured surface. To complement the table's aesthetic, selecting an edgebanding material that replicates the texture of the wood grain can enhance the overall appearance.

By utilizing the Homag Edgebander, which is capable of handling a variety of textures, you can seamlessly apply the matching edgebanding material, adding a cohesive and visually appealing touch to your project.

Streamlining Workflow and Material Handling

Efficiency can be significantly improved by optimizing your workflow and material handling processes.

Organizing your workspace is the first step toward improving efficiency. Consider creating dedicated stations for different stages of the edgebanding process, such as edgebanding preparation, adhesive application, and finishing.

By doing so, you create a clear and structured workflow that minimizes the time spent on searching for tools, materials, and equipment, ultimately improving overall productivity.

Implementing a reliable material handling system is another aspect that significantly contributes to efficiency.

This can involve using appropriate storage solutions, such as racks or shelves, to organize edgebanding materials based on size, type, or color.

By having a well-organized and easily accessible inventory of edgebanding materials, you can minimize downtime associated with searching for specific materials during the edgebanding process.

Embrace these practices, and you'll find yourself delivering high-quality results with exceptional efficiency, leading to satisfied customers and a thriving woodworking business.

Embracing Homag Edgebander Automation Features

The automation features of Homag Edgebander are designed to save you time and effort while maintaining exceptional quality.

Make use of features like automatic thickness adjustment, precision trimming, and glue application systems to streamline your edgebanding process.

These features not only enhance efficiency but also ensure consistent and accurate results.

For example: say you're working on a production line for a furniture manufacturer. By utilizing the automated features of Homag Edgebander, you can seamlessly process large volumes of edgebanding tasks with minimal human intervention. This allows you to focus on other critical aspects of production, resulting in improved efficiency and increased output.

Unlocking the Full Potential of Homag Edgebander

By following these tips and tricks, you can unlock the full potential of your Homag Edgebander, revolutionizing your woodworking operations.

From optimizing machine setup and selecting the right materials to streamlining workflow and embracing automation features, you'll witness a remarkable increase in efficiency and productivity.

Visit CarbideTooling.net today and explore their extensive range of Homag Edgebander tools and options, as well as other premium tooling products.

For More Information about Brandt Edgebander And SCM Edgebander Please Visit: Carbidetooling.net