𝗣𝗵𝗼𝘁𝗼𝗺𝗮𝘀𝗸 𝗜𝗻𝘀𝗽𝗲𝗰𝘁𝗶𝗼𝗻 𝗠𝗮𝗿𝗸𝗲𝘁 𝗙𝗼𝗿𝗲𝗰𝗮𝘀𝘁 𝗖𝗼𝘃𝗲𝗿𝗶𝗻𝗴 𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗘𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆, 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀, 𝗔𝗻𝗱 𝗙𝗮𝗯 𝗜𝗻𝘁𝗲𝗴𝗿𝗮𝘁𝗶𝗼𝗻 𝗚𝗹𝗼𝗯𝗮𝗹𝗹𝘆

The photomask inspection market is driven by equipment efficiency, automation solutions, and fab integration in semiconductor manufacturing. Manufacturers are increasingly investing in advanced inspection systems that streamline workflows, reduce human intervention, and improve defect detection accuracy. Automated platforms enable real-time analysis, predictive maintenance, and enhanced process monitoring. High-resolution imaging and AI-driven analytics allow early detection of defects, optimize lithography and etching processes, and enhance yield. Integration with fab operations ensures seamless process control, consistent production quality, and operational efficiency. Adoption of these technologies strengthens competitiveness, supports high-volume production, and improves global semiconductor manufacturing outcomes.

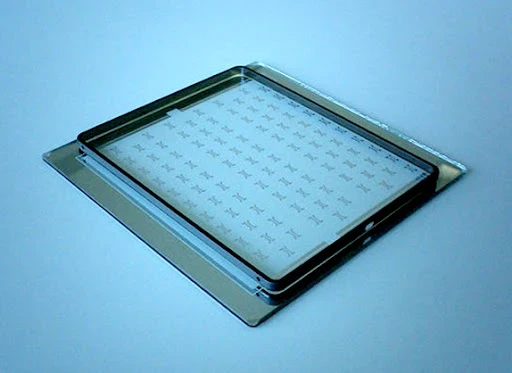

𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗘𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆 𝗶𝗻 𝗣𝗵𝗼𝘁𝗼𝗺𝗮𝘀𝗸 𝗜𝗻𝘀𝗽𝗲𝗰𝘁𝗶𝗼𝗻

High-performance inspection equipment is essential for identifying sub-nanometer defects in photomasks. Equipment efficiency improves throughput, reduces false positives, and ensures reliable defect classification. Multi-sensor platforms, automated calibration, and predictive maintenance contribute to consistent operation. Optimized equipment performance minimizes downtime, supports high-volume production, and enhances overall fab productivity. Efficient equipment allows semiconductor fabs to maintain quality standards while increasing yield and operational efficiency.

𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀

Automation solutions streamline inspection workflows, reduce human errors, and improve consistency. Automated defect classification, real-time analysis, and process integration enable faster decision-making. Automation enhances throughput, reduces operational costs, and ensures timely corrective actions in fab operations. Predictive maintenance and automated reporting further improve productivity and reduce downtime. Automated inspection systems are crucial for scaling high-volume semiconductor manufacturing while maintaining quality standards.

𝗙𝗮𝗯 𝗜𝗻𝘁𝗲𝗴𝗿𝗮𝘁𝗶𝗼𝗻

Integration of photomask inspection systems with fab operations allows seamless process monitoring and control. Inspection data is used to adjust lithography, etching, and deposition processes in real-time. Fab integration ensures defect trends are analyzed promptly, process deviations are corrected, and yield is optimized. Integration also facilitates predictive maintenance, reduces downtime, and enhances operational efficiency. Proper fab integration is essential for maintaining consistent semiconductor manufacturing quality and maximizing production output.

𝗔𝗱𝘃𝗮𝗻𝗰𝗲𝗱 𝗜𝗺𝗮𝗴𝗶𝗻𝗴 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗲𝘀

High-resolution imaging systems, including optical, electron beam, and hybrid platforms, are essential for accurate defect detection. Advanced imaging allows visualization of nanoscale features, improving defect classification and reducing false positives. Imaging innovations support new lithography processes, such as EUV and multi-patterning, enabling precision fabrication. Accurate imaging ensures reliable process monitoring, maintains quality standards, and supports high-volume production.

𝗠𝗮𝗰𝗵𝗶𝗻𝗲 𝗟𝗲𝗮𝗿𝗻𝗶𝗻𝗴 𝗮𝗻𝗱 𝗣𝗿𝗲𝗱𝗶𝗰𝘁𝗶𝘃𝗲 𝗔𝗻𝗮𝗹𝘆𝘁𝗶𝗰𝘀

Machine learning and predictive analytics improve defect detection, process optimization, and operational efficiency. Algorithms analyze inspection datasets to detect subtle anomalies and predict potential process deviations. Predictive analytics enables proactive process adjustments, reducing wafer scrap and improving yield. AI-powered insights accelerate decision-making, improve classification accuracy, and enhance fab efficiency. Machine learning applications are integral to modern photomask inspection systems.

𝗥𝗲𝗮𝗹-𝗧𝗶𝗺𝗲 𝗠𝗼𝗻𝗶𝘁𝗼𝗿𝗶𝗻𝗴

Real-time monitoring provides immediate insight into defects and process anomalies. Continuous feedback allows for timely corrective actions, reducing downtime and improving production efficiency. Integration with fab management systems supports process optimization, yield enhancement, and operational consistency. Real-time monitoring ensures consistent quality and maximizes semiconductor fabrication output.

𝗟𝗲𝗮𝗿𝗻 𝗠𝗼𝗿𝗲:https://www.pristinemarketinsi....ection-market-report