Your ideas should not get simply generic components — they should get components as unique as every plan you have — components that make it come true.

No matter if you’re setting a new standard in aerospace technology, creating the next generation of medical devices, or developing revolutionary robotics, the proper kind of a bespoke production process is a critical component for such a development.

Find out how parts made to order, to the required specifications, can be a driving force for creativity and putting you a step ahead of your competitors in today’s world.

Tailored Component Creation

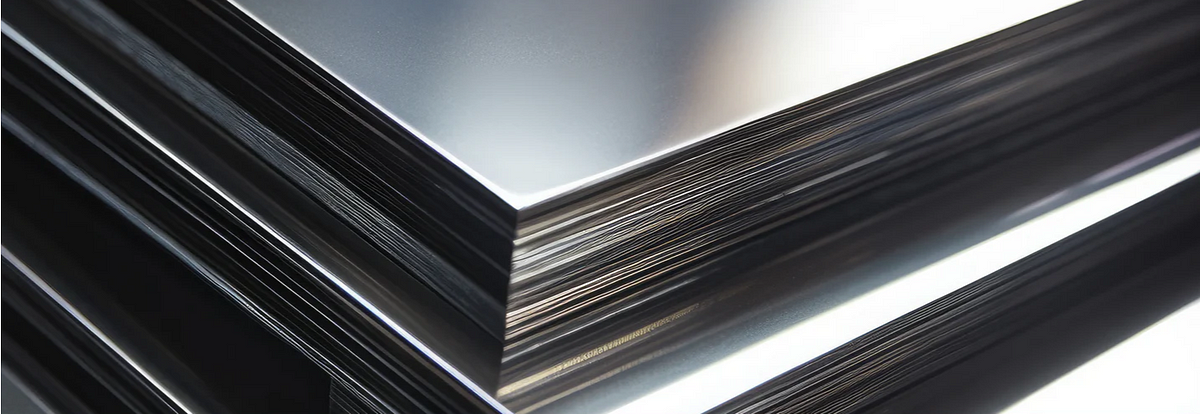

Custom component manufacturing entails the practical application of designs that are developed by the various engineering disciplines. They employ premium methods such as injection molding, computer numerical control machining, and metal additive manufacturing, to achieve the right and precise components that are challenging to get by traditional methods. Since custom component manufacturing concentrates on achievement of high quality, it is a surety that every component provided will meet the intended function accordingly.

From Molten Material to Masterpiece

The Injection molding process is more of craftsmanship. One is by heating the raw material to the extent that it turns molten, before it is injected into a specially Engineered mold. For the molded part, after it has been cooled to complement the required temperature for use, the part is ejected. This process is widely used in medical and automotive industries because of the emphasis on the reliability of the product.

For more: https://medium.com/@norck2805/....unlock-innovation-wi