Maximize Packaging Speed With Smart Paper Roll Cutters

Modern warehouses, e-commerce brands, and retail counters rely on fast, clean cutting to keep orders moving, which is exactly where a well-designed paper roll cutter becomes invaluable #efficiency. In a single motion, staff can pull the sheet length they need and cut it accurately, preventing jagged edges and wasted material. Instead of fighting with scissors or tearing paper by hand, the right roll paper cutter turns every workstation into a tidy, efficient mini-packing line that consistently delivers professional-looking results #packaging.

A dedicated roll cutter also supports better cost control because each sheet length becomes repeatable, which reduces off-cuts and overuse of wrapping material. When a kraft roll sits on a stable dispenser, it feeds smoothly while the blade glides across, producing straight cuts that improve the appearance of gift wrapping, protective packing, or void fill #cutting. For businesses that handle seasonal peaks or bulk shipments, upgrading from manual tearing to a purpose-built paper roll cutting machine can quickly translate into measurable savings in both time and material.

Safety and ergonomics are just as important as speed in busy environments. A sturdy roll paper cutter mounted to a table or wall keeps the roll securely in place, so workers avoid bending, twisting, or wrestling with heavy rolls throughout the day #workflow. One-handed cutting designs allow staff to hold products with the other hand, reducing the risk of drops or damaged items. By combining these ergonomic gains with consistent output, a reliable roll cutter supports healthier teams and smoother workflows, especially in facilities that run multiple shifts.

Versatility is another reason many operations standardize on roll paper cutters across departments https://partymakerdiscountmega....tter-for-clean-cuts/ . A single unit can handle butcher paper in a deli, kraft paper in a warehouse, and decorative wrap in a retail shop, simply by swapping rolls to match the task at hand #productivity. Because the blade tracks along a guided bar, even inexperienced staff can cut straight lines for tray lining, table covering, or art-room projects without extensive training. Over time, this flexibility makes the paper roll cutter a central tool that supports branding, protection, and presentation in one compact footprint.

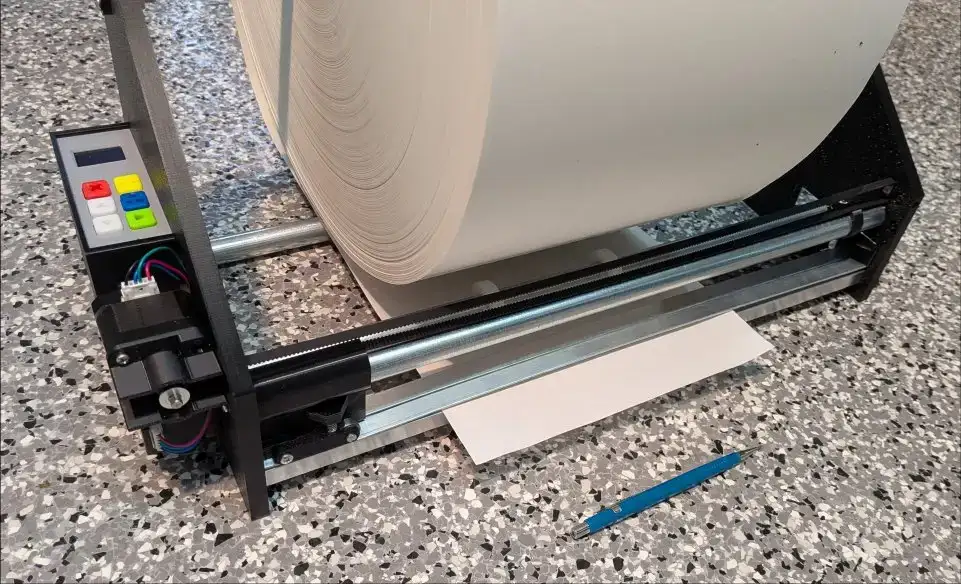

For growing brands, scalability matters, and that is where more advanced models, such as semi-automatic or automated paper roll cutter systems https://www.mixcloud.com/krexil/ , become attractive #fulfillment. These units allow operators to set a target length and repeat count, ensuring each sheet is identical for batch-packing, print preparation, or production runs. By aligning packaging processes with a consistent cutting system, companies can track consumption more accurately and forecast replenishment needs, supporting lean inventory practices without sacrificing responsiveness.

Even small businesses and home-based sellers now see the benefit of investing in a quality roll paper cutter https://www.brownbook.net/busi....ess/52917693/krexil/ . With online orders demanding quick turnaround and neat presentation, a cleanly cut sheet of kraft or tissue paper helps elevate perceived value compared to items wrapped haphazardly. When customers unbox a parcel and see tidy folds and smooth edges, they associate that care with the brand, reinforcing trust and encouraging repeat purchases that justify the small upfront investment in cutting hardware.

News Feed

News Feed  Albums

Albums  Popular Posts

Popular Posts  Memories

Memories  Pokes

Pokes  Blog

Blog  Market

Market  Directory

Directory  Events

Events  Games

Games  Jobs

Jobs  Offers

Offers  Find friends

Find friends  Common Things

Common Things  Fundings

Fundings