An Overview of Reverse Engineering Services

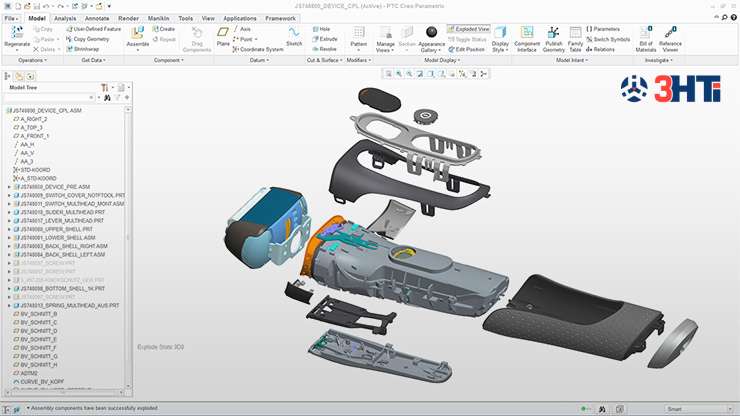

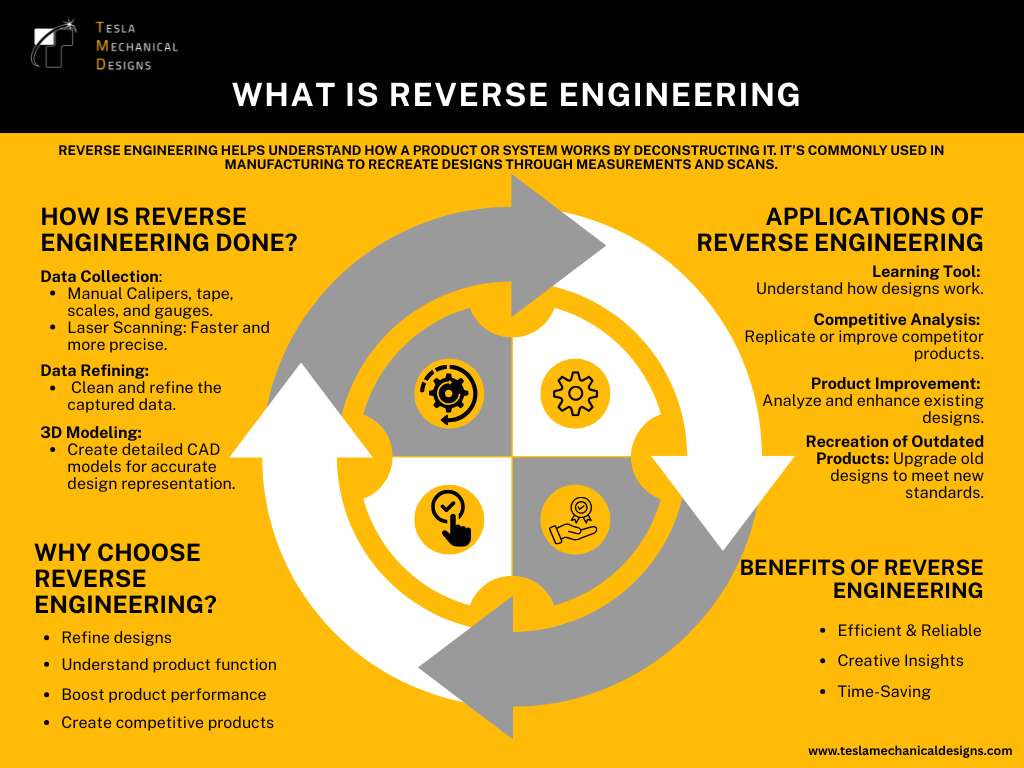

Reverse engineering is the process of deconstructing a product to understand how it works and recreate its design through measurements and scans. This method is used in manufacturing to improve or replicate existing designs. The process begins with data collection, using tools like calipers and laser scanning for accurate measurements. The data is then refined and used to create a detailed 3D model, allowing for precise design representation.

Reverse engineering is widely used for improving product designs, understanding competitor products, and upgrading outdated items to meet new standards. It is highly efficient and time-saving, helping engineers gain insights into design functionality and boost performance.

Learn More: https://www.teslamechanicaldes....ngineering-services/

#reverseengineering, #productdesign, #cadmodeling, #manufacturing, #engineeringservices

News Feed

News Feed  Albums

Albums  Popular Posts

Popular Posts  Memories

Memories  Pokes

Pokes  Blog

Blog  Market

Market  Directory

Directory  Events

Events  Games

Games  Jobs

Jobs  Offers

Offers  Find friends

Find friends  Common Things

Common Things  Fundings

Fundings