Reliable Metal 3D Printing Services | Precision Manufacturing with DMLS Technology

Explore Tesseract 3D’s expert metal 3D printing services, utilizing Direct Metal Laser Sintering (DMLS) technology to produce high-quality, durable metal parts with unmatched precision. Our DMLS service is ideal for complex geometries and high-strength applications in industries such as aerospace, automotive, and medical. By directly sintering metal powder layer by layer, we achieve intricate designs that meet stringent performance standards. With reduced lead times and minimal material waste, our metal 3D printing service is a cost-effective choice for both prototypes and production-ready components. Discover how our expertise can bring your metal designs to life with precision and reliability.

https://www.tesseract3d.com/dmls-3d-printing/

@tesseract

Direct Metal Laser Sintering Unlocks Flexibility!

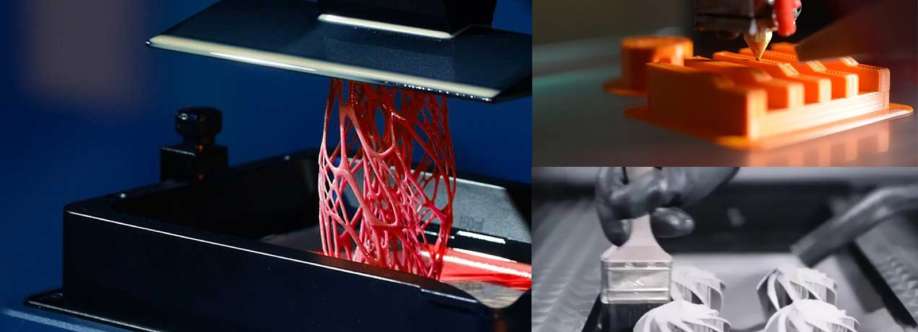

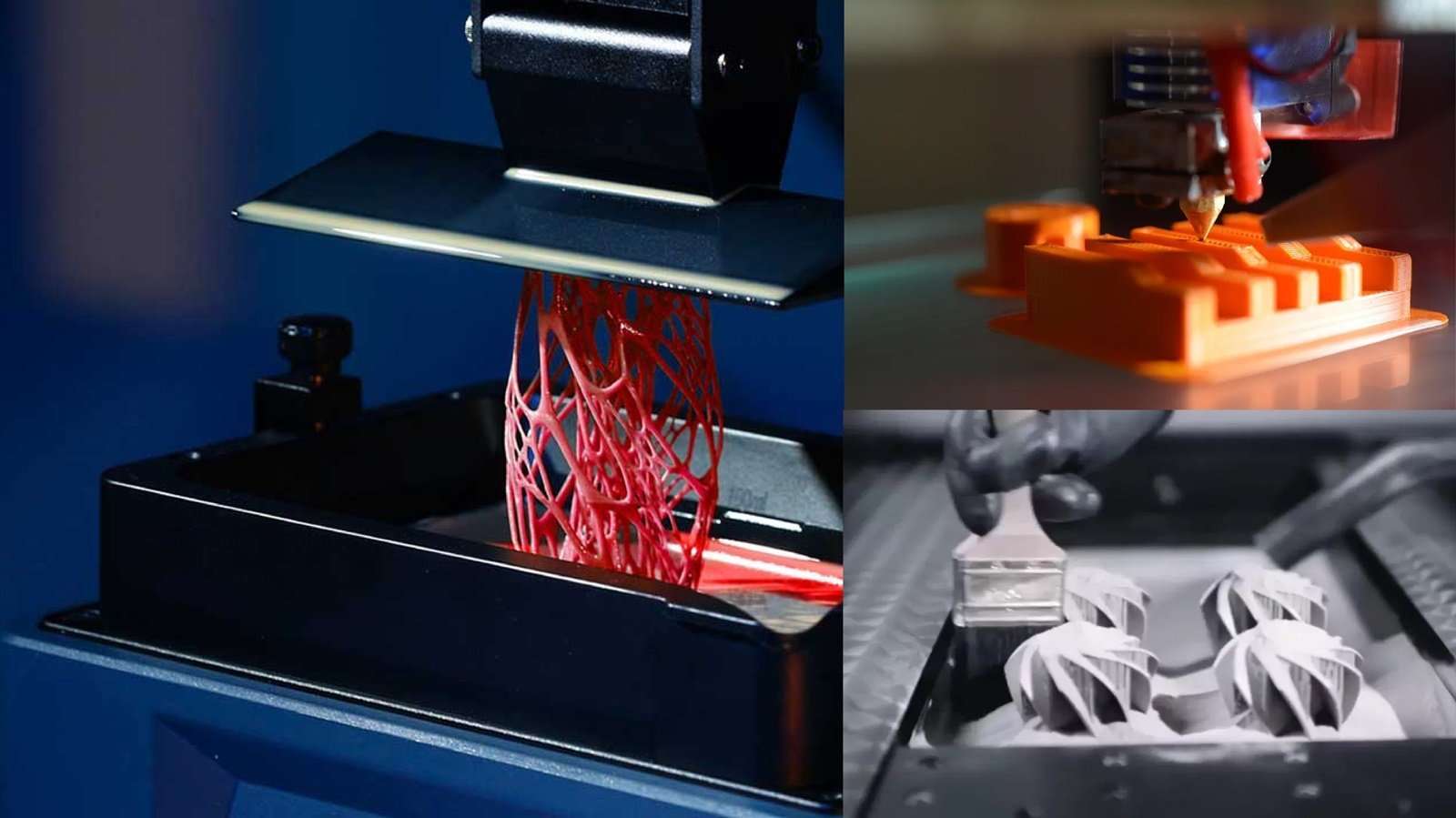

The Power of Direct Metal Laser Sintering (DMLS):

Direct Metal Laser Sintering (DMLS) represents a breakthrough in metal 3D printing service, pushing the boundaries of what’s possible with additive manufacturing. Utilizing high-wattage lasers, DMLS fuses powdered metals and alloys into robust, functional metal structures. This process excels in shaping materials like aluminium, stainless steel, MS, and titanium, resulting in denser and superior parts than traditional methods.

Unmatched Design Potential:

One of the most compelling aspects of DMLS is its limitless design potential. Unlike conventional manufacturing techniques constraining part geometry and complexity, DMLS allows for creating intricate shapes, internal channels, and detailed surface textures. This flexibility makes it an invaluable tool for industries demanding high precision and customization, such as the Oil and gas, Aerospace, Automotive, Defense, and Medical sectors. The ability to produce compact components with complex anatomical features opens new avenues for innovation and efficiency.

Tesseract’s Role in Advancing Technology:

At the forefront of this technology, Tesseract harnesses the power of DMLS to offer cutting-edge solutions in the metal 3D printing service domain. By leveraging DMLS’s advanced capabilities, Tesseract delivers components that meet the stringent requirements of various high-tech industries. This demonstrates the potential of DMLS and highlights how innovative manufacturing processes can drive progress and transform traditional approaches.

Explore the website to discover more services: https://www.tesseract3d.com/dmls-3d-printing/

#tesseract3d #3dprinting #metal3dprinting

Tesseract is your ultimate product development partner, transforming concepts into reality. With expert design, cutting-edge 3D printing, and top-tier manufacturing, we guide your innovations from idea to finished product seamlessly.