The automotive industry in India is growing rapidly, and the demand for reliable and efficient automotive batteries is also increasing. Automotive batteries are essential components of any vehicle and play a vital role in its performance. With the ever-increasing demand for automotive batteries, India is a prime market for battery manufacturers. In this article, we will explore the possibilities of automotive battery manufacturing in India and the various opportunities it presents.

What are Automotive Batteries?

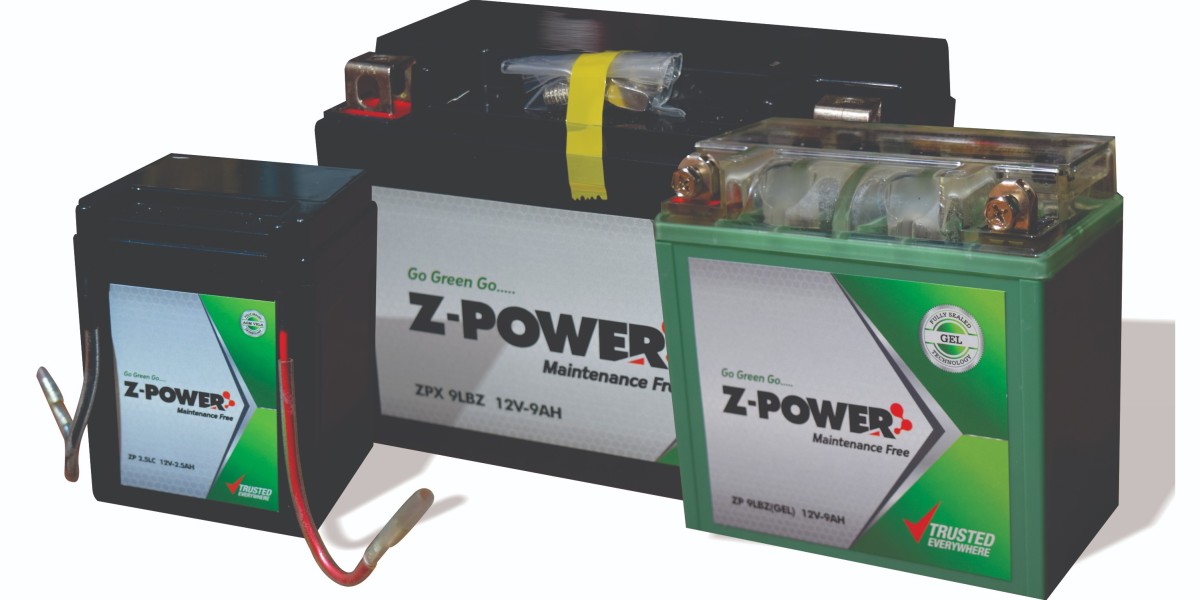

Automotive batteries are rechargeable batteries that are used to provide power to the electrical and electronic components of a vehicle. These batteries are typically lead-acid batteries and are available in a range of sizes and capacities, depending on the type of vehicle. Automotive batteries are designed to deliver a steady and efficient source of power and are capable of providing power even in extreme weather conditions.

Advantages of Automotive Battery Manufacturing in India

Cost-Effectiveness: India is a cost-effective destination for automotive battery manufacturers in india. It has easy access to raw materials and components, and the labor costs are low compared to other countries. As a result, manufacturers can produce high-quality automotive batteries at a lower cost.

Growing Market: The automotive industry in India is growing rapidly, and the demand for automotive batteries is also increasing. This presents an opportunity for battery manufacturers to tap into the growing Indian market and benefit from its potential.

Skilled Labor: India has a large pool of skilled labor that can be tapped into for the production of automotive batteries. The availability of trained and qualified personnel provides manufacturers with a competitive advantage and allows them to produce quality products.

Government Support: The Indian government provides various incentives and subsidies for manufacturers that set up automotive battery manufacturing plants in India. This makes it easier and more cost-effective for manufacturers to set up their operations in India.

Challenges of Automotive Battery Manufacturing in India

Capital Investment: Setting up an automotive battery manufacturing plant in India requires substantial capital investment. This can be a major constraint for new entrants in the market, as the investment required is often too high for them to bear.

Lack of Infrastructure: The lack of proper infrastructure is a major challenge for automotive battery manufacturers in India. Poor roads, inadequate power supply, and inefficient logistics can lead to delays in production and delivery.

Regulatory Hurdles: The Indian government has laid down stringent regulations for automotive battery manufacturing in India. These include requirements such as obtaining licenses and approvals from local authorities, which can be a time-consuming and expensive process.

Low Quality Materials: The quality of the raw materials used for automotive battery manufacturing in India is often low. This can lead to defective products, which can cause damage to the vehicle and pose a safety hazard.

Conclusion

The automotive battery manufacturing industry in India is growing rapidly and presents immense opportunities for manufacturers. However, the industry is also facing challenges such as capital investment, lack of infrastructure, regulatory hurdles, and low quality materials. Despite these challenges, the future of automotive battery manufacturing in India looks bright and presents a good opportunity for manufacturers to tap into the potential of this growing industry.